Ensuring the structural integrity of a plastic trolley under heavy load conditions involves several considerations related to design, material selection, testing, and proper usage guidelines. Here are key strategies to ensure the structural integrity of a plastic trolley when it is subjected to heavy loads:

Design Considerations

Material Selection:Choose high-quality, durable plastics that are specifically engineered for load-bearing applications. Common materials include high-density polyethylene (HDPE), polypropylene (PP), or engineering plastics like ABS (Acrylonitrile Butadiene Styrene).

Ensure the plastic material selected has a high tensile strength and impact resistance suitable for heavy loads.

Structural Design:Design the trolley with a robust frame or chassis that distributes the load evenly across the structure.

Incorporate reinforcements such as ribs, gussets, or support bars in critical areas to enhance strength and prevent deformation under load.

Load Capacity Rating:Clearly define and communicate the maximum load capacity of the trolley. This information should be prominently displayed or included in product documentation.

Ensure the load capacity rating exceeds the anticipated maximum loads the trolley will encounter in typical use scenarios.

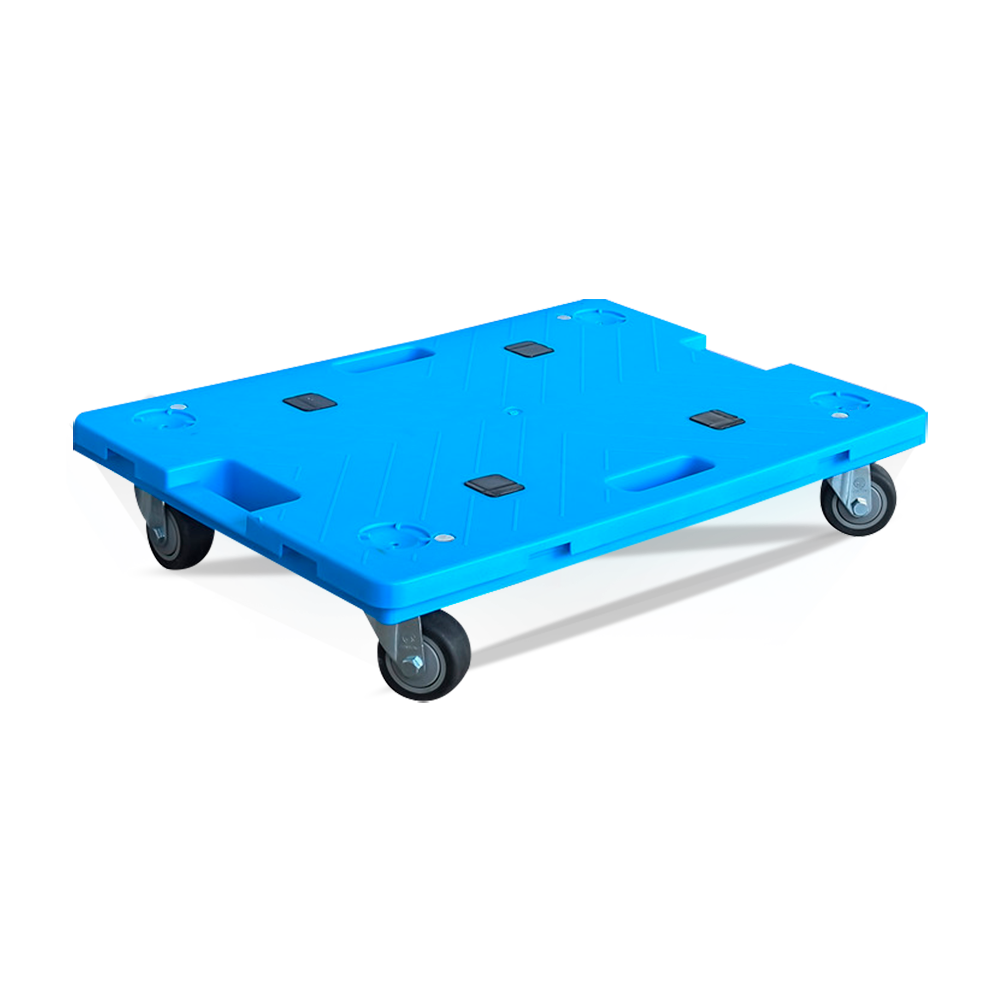

Wheel and Caster Design:Select wheels or casters that are rated for the anticipated load and provide smooth movement under load conditions.

Consider larger diameter wheels for better weight distribution and stability, especially when moving heavy loads over uneven surfaces.

Testing and Quality Assurance

Load Testing:Conduct rigorous load testing during the product development phase to simulate real-world conditions.

Test the trolley with loads that exceed its rated capacity to ensure it can withstand unexpected stresses and remains structurally sound.

Quality Control:Implement strict quality control measures during manufacturing to monitor material consistency, dimensional accuracy, and assembly integrity.

Perform regular inspections and quality audits to detect any defects or weaknesses that could compromise structural integrity.

Proper Usage Guidelines

User Guidelines:Provide clear guidelines and instructions for proper use and loading of the trolley.

Educate users on the maximum load capacity, distribution of weight on the trolley, and safe handling practices to avoid overloading or uneven loading that could stress the structure.

Maintenance and Inspection:Recommend regular maintenance checks to ensure the trolley remains in optimal condition.

Inspect for signs of wear, stress fractures, or degradation of structural components that could affect load-bearing capabilities.

Continuous Improvement

Feedback and Iteration:Gather feedback from users and stakeholders regarding the performance of the trolley under heavy load conditions.

Use feedback to identify areas for improvement in design, materials, or manufacturing processes to enhance structural integrity.

Ensuring the structural integrity of a plastic trolley under heavy load conditions requires a holistic approach that includes robust design, appropriate material selection, rigorous testing, clear usage guidelines, and continuous quality improvement. By addressing these aspects comprehensively, manufacturers can deliver plastic trolleys that meet or exceed performance expectations in demanding industrial, commercial, or residential applications.

ZHEJIANG ZHENGJI PLASTIC INDUSTRY CO. ,LTD born in 1990’s is a professional manufacturer of plastic collapsible boxes, folding crates, storage bins, moving dolly and other plastic products items, etc.

+0086-573-80886008

+0086-573-80886008Copyright © Zhejiang Zhengji Plastic Industry Co.,Ltd.All Rights Reserved.